High speed Pulverizer/Granulator

Introduction

Huanchuang Granulators are high speed granulation machines designed for reducing various materials and recycling varities of waste. These machines are ideal for processing a multitude of materials including plastics, rubber, copper cable and organics etc. They are ideal secondary pulverizer of the multitude production line. Output particle size will be 5-60mm.

· Compact design minimizes on-site space requirements

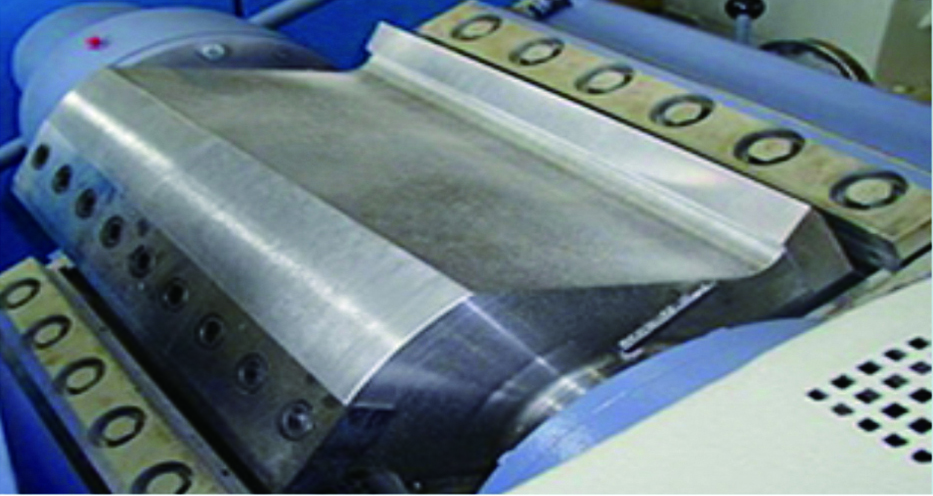

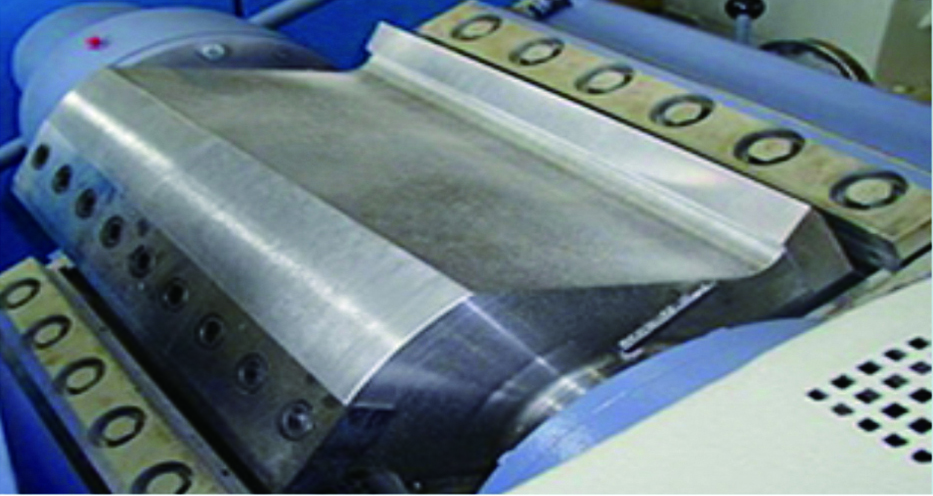

· Inclined, split cutting chamber design

· Oversized, outboard spherical rotor bearings – prevents bearing damage due to product migration

· Precision machined rotors (Forward set V-Rotor as standard)

· Replaceable wear plates at either end of the rotor shaft

· Standard machines are prepared for air extraction

· Stand Alone Electrical Control Panel - Siemens PLC’s

· Tested, Approved and Certified to the applicable CE safety standardsRotor and Blade

Structure features

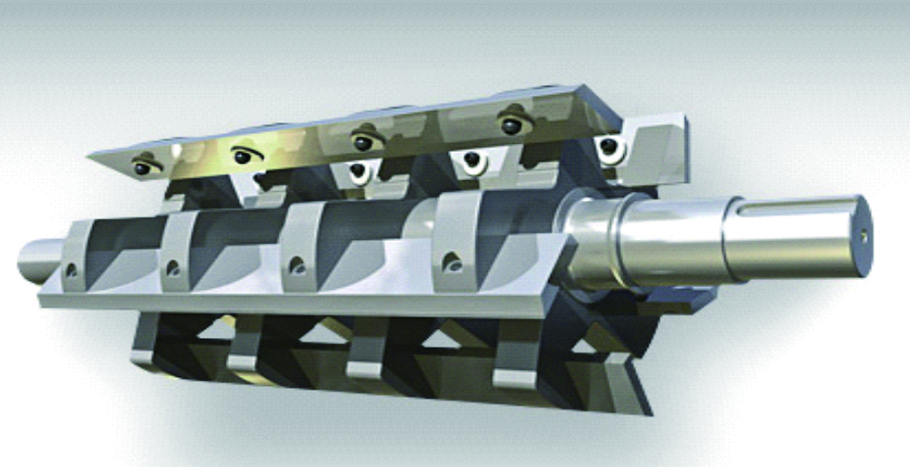

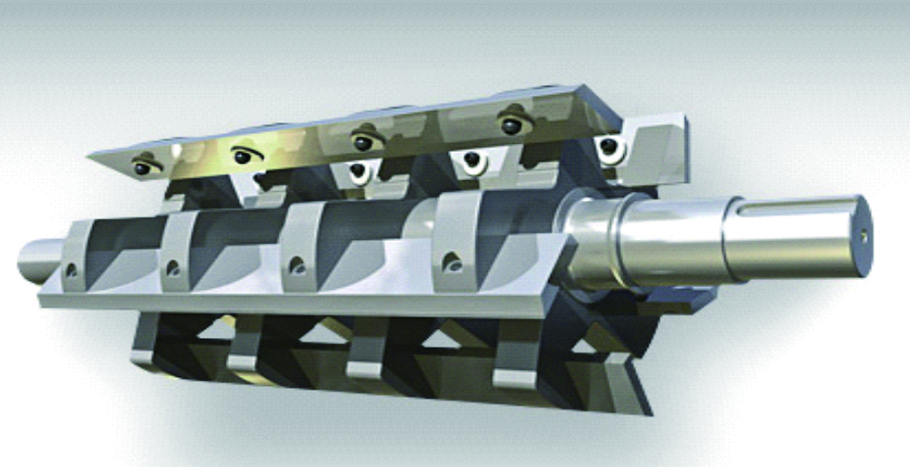

1. R-type Rotor

This rotor is main suitable for pulverizing hard pipe, wire, thick wall material and sheets etc.

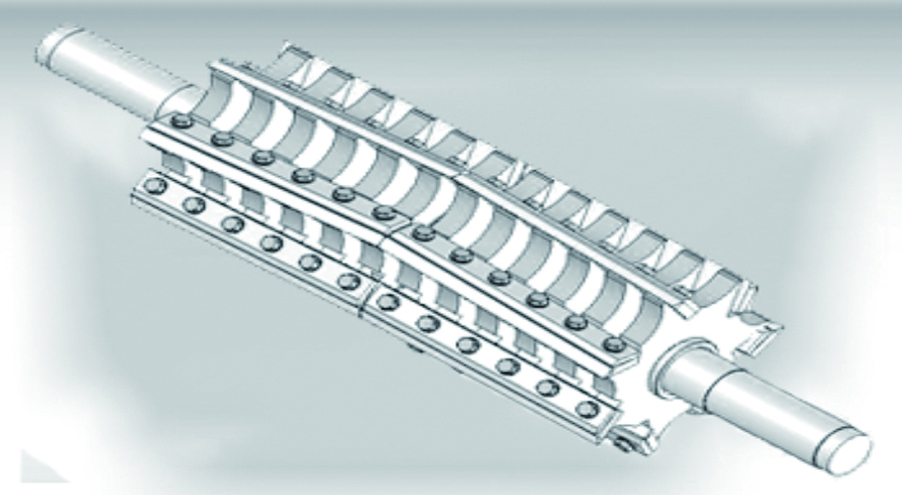

2. V-type Rotor

This rotor is main suitable

for pulverizing PET bottles,

normal pipe, tube, film etc.

3. S-type Rotor

This rotor is main suitable for

pulverizing very hard materials

such as rubber head, thick wall

pipe, thick board, power cable

or line pulverizing

RDF(20-30mm).

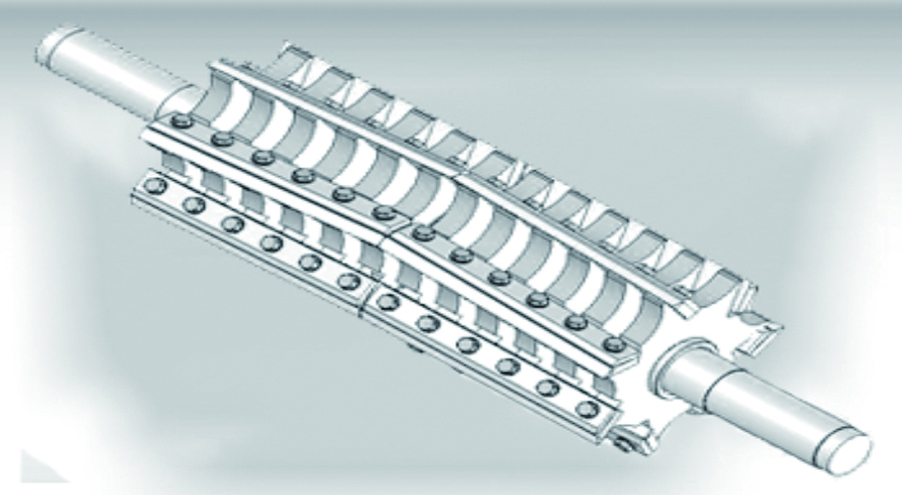

4. K-type Rotor

This type is suitable to secondary

pulverizing treatment for any

material besides metallic material.