|

Search Products |

|

|

|

|

Wastewater grinder |

|

|

|

|

Solid waste recycling system |

|

|

|

|

Huanchuang (Xiamen) Technology Co.,Ltd

Phone: ��+86 592 5029670

Fax: +86 592 5029673

Email:info@hcwater.com

Add; 22 Guanri Road, Software Park 2, Xiamen, China

|

|

|

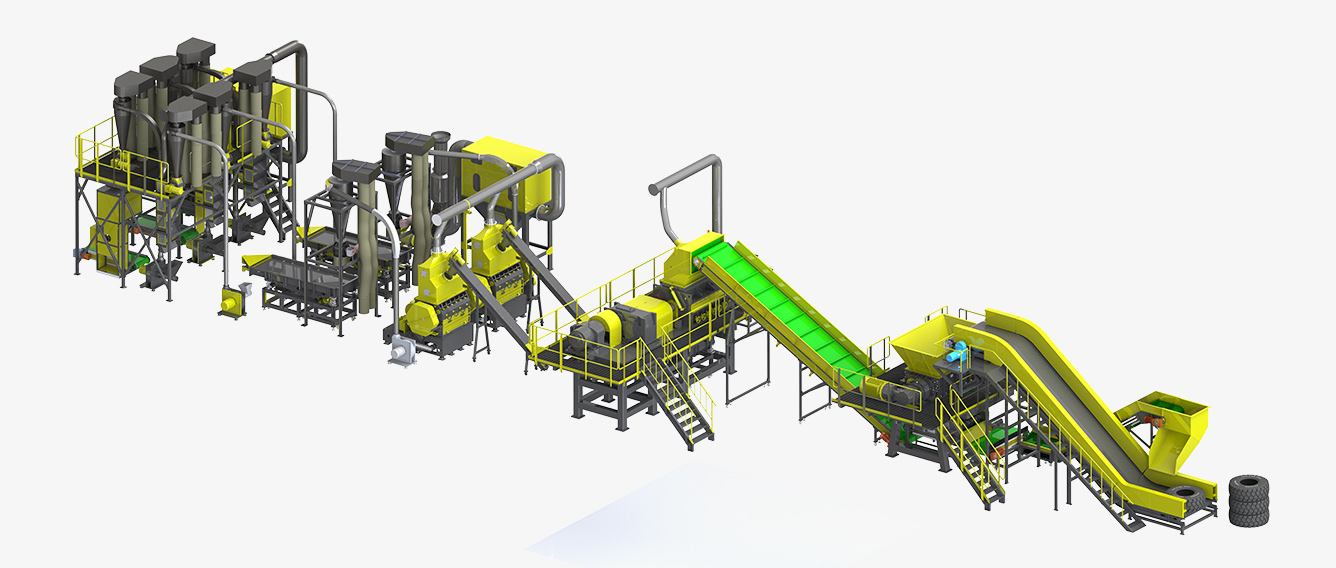

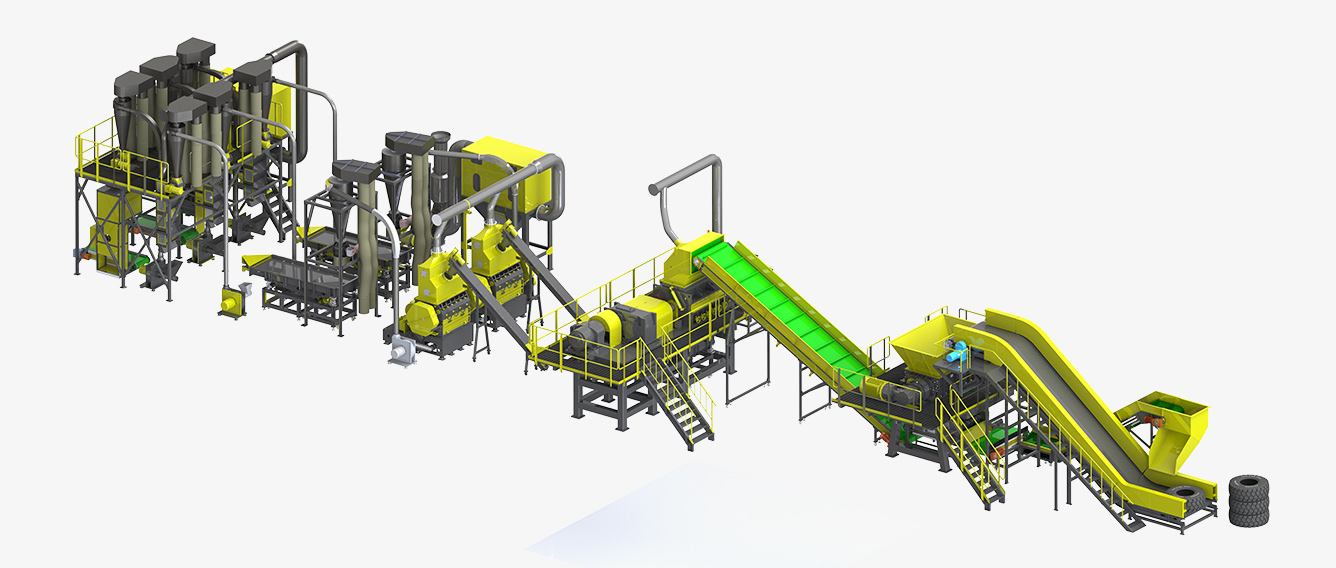

Waste Tire Pulverizing, Separating Recycling System

Material and Final products

-

Tire waste steel wir Tire waste steel wir

-

Tire powder Tire powder

-

Tire granule Tire granule

-

Tire fiber Tire fiber

Product advantage

Scrap tires are a severe problem for the Earth environment. The more and more increasing traffic volume results in quick growing tire mountains. HC tire recycling system was born to solve the problems.

With advantage of full-automatic(without steel wire manual debeading) normal temperature processing and non-secondary pollution, the system are easy to access by operator without special training.

|

Main Equipment and Technical Data

1.Pre-shredding

The Supper chopper is a powerful shredding blade and capable of processing complete car or truck tires to approximately 50-300m scraps.

It��s a low speed and high torque shredder with double shaft. Debeading of the tires will not be required prior to processing in HC supper chopper...

2.Secondary shredding

HC series raspers with serrated edged blade are an aggressive cutting machine which is well suited to secondary processing of pre-shredded tire fraction to remove steel wire. The fractions from rasper can be used for TDF(Tire Derived Fuel)...

3.Steel wire separation

The hanging magnetic separator on the belt conveyor pick up the steel wires from rubber. Due to the unique cutting design of the raspers, the steel wires take very low rubber contamination which is easy for further processing....

4.Fine pulverizer / granulator

HC series pulverizer with specific rotor design for rubber fine granulation are set at the last stage of size reduction. The open design of the rotor minimizes heat production. The desired size can be set by changing of screens....

5.Size classifying

The vibration table sort out different size of rubber crumbs for further processing. Oversize crumbs are sending back to the fine pulverizer for size reduction. The vibrating table are connected to the aspirator. a certain part of textile are separated at this stage....

6.Textile separation

The speed variable zig-zag classifiers are suitable to separate textiles from variety of rubber crumbs.

The drum magnetic separator is installed under the classifier for fine steel separation to warrant the high purity of rubber.A pulse deduster is connected with the system for aspiration....

|

| |

|

|

|